The impact of prototyping in engineering Rubber Keypads for mass production

Discovering the Diverse Types and makes use of of Rubber Keypads in the Modern Technology Landscape Today

Rubber keypads have developed themselves as vital elements in various technological applications. Their flexibility makes them suitable for consumer electronic devices, industrial devices, and medical tools. As these keypads remain to develop, brand-new personalization options and layout fads emerge. This triggers a better assessment of their benefits and manufacturing procedures. Comprehending these components may disclose why rubber keypads remain a favored option in the modern technology landscape. What exists in advance for this functional component?

Review of Rubber Keypads

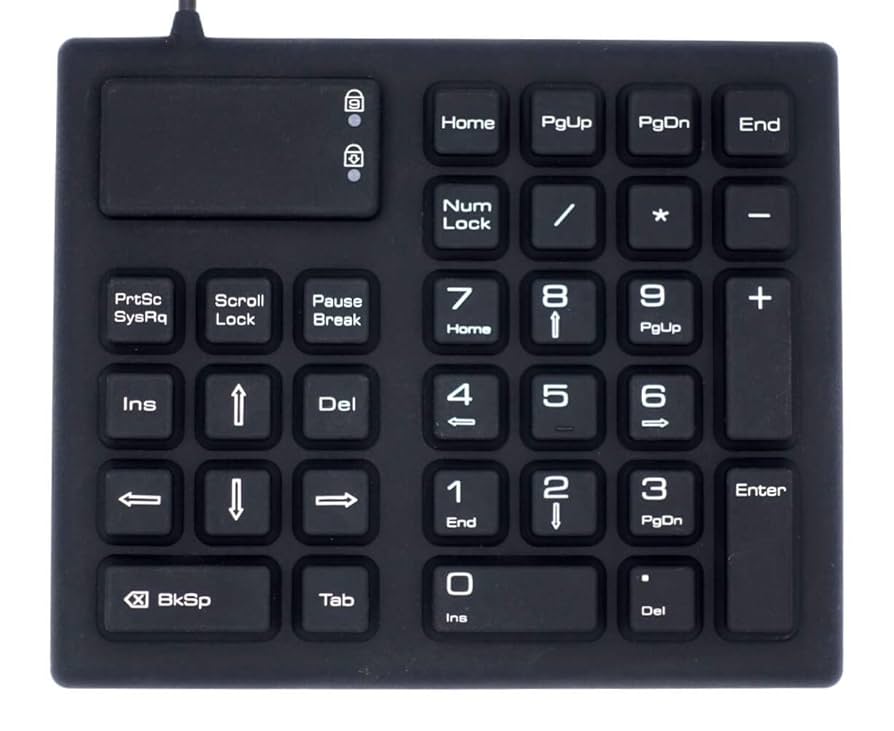

Rubber keypads act as an essential element in different electronic gadgets, using a responsive user interface for individual communication. These keypads are normally made from silicone or rubber products, which supply flexibility and durability. Their style commonly incorporates increased icons or letters, boosting usability by allowing customers to feel the tricks - Rubber Keypads. Rubber keypads are resistant to dirt, dampness, and put on, making them suitable for demanding settings

Moreover, they can be tailored concerning size, form, and shade, enabling makers to create one-of-a-kind user interfaces tailored to particular items. The manufacturing process usually entails methods such as molding and printing, making certain top notch result. Therefore, rubber keypads not only enhance performance yet additionally contribute to the total visual appeals of the device. With these attributes, rubber keypads stay a preferred option for both makers and customers, stressing their relevance in the innovation landscape.

Common Applications in Consumer Electronic Devices

While many digital devices count on touchscreens for user communication, rubber keypads proceed to play a vital function in customer electronics. These keypads are widely utilized in devices such as remote controls, gaming controllers, and family home appliances, where responsive comments enhances customer experience. Their toughness and resistance to put on make them perfect for gadgets frequently based on heavy usage.

Rubber keypads are likewise preferred in mobile gizmos and mobile phones, where small styles necessitate dependable and receptive input techniques. The capability to tailor the shape and appearance of rubber keypads enables suppliers to develop one-of-a-kind styles that appeal to customers. Additionally, the soft touch of rubber gives convenience throughout long term usage, making these keypads a favored selection for devices requiring extensive communication. On the whole, rubber keypads continue to be a critical part in the customer electronic devices landscape, integrating functionality with easy to use attributes.

Role in Industrial and Medical Tools

Rubber keypads play an important role in both commercial and medical equipment, providing toughness and dependability in demanding settings. In industrial settings, they are frequently used in control panels and equipment, improving operator interaction with complex systems. In the medical field, rubber keypads assist in easy to use interfaces for gadgets that call for accuracy and hygiene.

Industrial Tools Applications

Keypads play a crucial duty in the capability and individual experience of medical and industrial devices. In industrial settings, rubber keypads provide a robust interface for machinery and control systems, allowing drivers to easily input commands and change settings. Their resistance to dirt, dampness, and chemicals guarantees reliability under rough conditions common of factories and manufacturing plants. Furthermore, the tactile responses used by rubber keypads improves user communication, minimizing the probability of input mistakes. In addition to typical machinery, these keypads are indispensable in automated systems and robotics, where precision is critical. The adaptability of rubber keypads in numerous commercial applications highlights their importance in improving functional effectiveness and guaranteeing security in complex atmospheres.

Medical Gadget Integration

As medical devices increasingly call for easy to use user interfaces, the assimilation of rubber keypads has actually become important in ensuring reliable communication between medical care specialists and tools. These keypads provide responsive comments, facilitating user-friendly procedure even in high-pressure environments. Their longevity and resistance to harsh cleansing agents make them suitable for clinical settings, where health and long life are vital. Additionally, rubber keypads can be personalized to include various shapes, sizes, and shades, enhancing visual recognition and availability for customers. This flexibility enables the development of specialized controls customized to particular clinical functions, enhancing total efficiency. As a result, the function of rubber keypads in clinical tool assimilation not just boosts functionality but additionally advertises client safety and functional integrity in health care settings.

Customization Options and Design Trends

Current design patterns stress minimalism and functional designs, focusing on individual convenience and instinctive communication. Custom-made logos and branding can be integrated right into keypads, enabling companies to maintain a natural brand identity across their products. In addition, improvements in producing methods, such as silicone molding, have actually made it less complicated to achieve complex layouts and personalized layouts.

Benefits of Rubber Keypads Over Various Other Kinds

Rubber keypads are additionally recognized for their resilience and resistance to environmental aspects. They can stand up to wetness, dirt, and temperature level variations, making them ideal for outside or industrial settings. In addition, rubber keypads are often quieter than their plastic or steel equivalents, minimizing environmental pollution in shared settings.

Furthermore, the cost-effectiveness of rubber keypads makes them an eye-catching alternative for producers. Their lightweight nature adds to decrease shipping costs, while their personalized designs satisfy particular branding demands. On the whole, rubber keypads stand for a reliable and functional solution in the modern technology landscape.

Production Techniques for Top Quality and Toughness

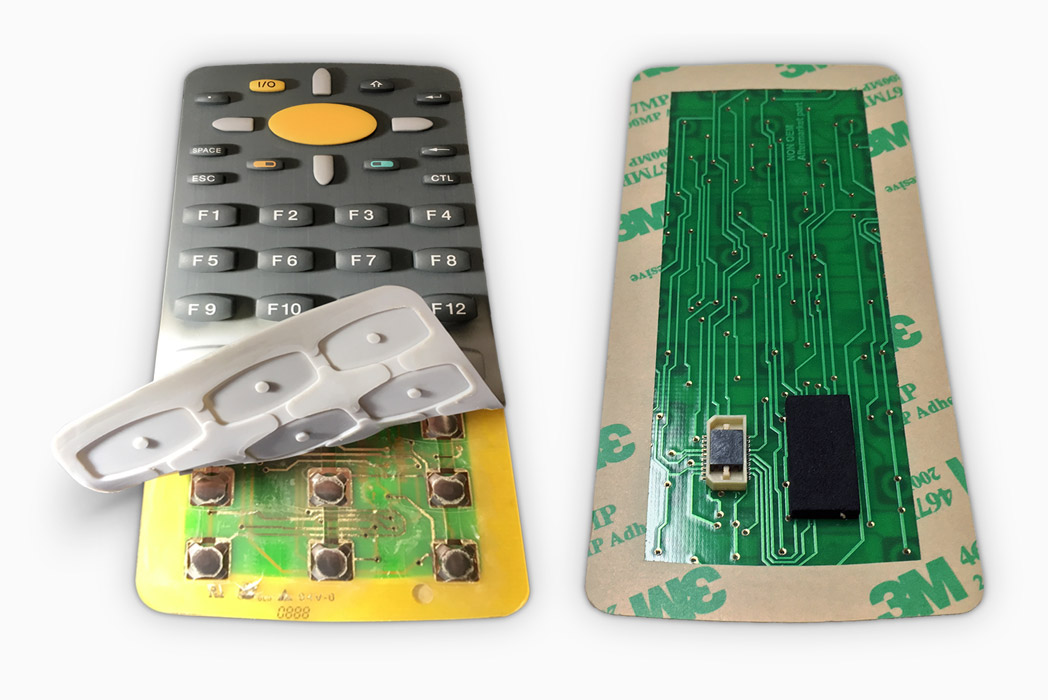

In the manufacturing of rubber keypads, the selection of suitable materials and molding processes plays an important role in establishing total top quality and durability. Various molding techniques, such as compression and shot molding, substantially influence the final item's performance. Recognizing these aspects is crucial for accomplishing optimal cause i loved this rubber keypad production.

Molding Procedures Described

A selection of molding processes play Rubber Keypads a crucial duty in the production of rubber keypads, making certain both high quality and durability. The most usual methods consist of compression molding, transfer molding, and shot molding. Compression molding entails placing rubber in a heated mold and mildew, where warmth and pressure form it into the preferred kind. Transfer molding allows for more specific control over product circulation and is suitable for complicated styles (Rubber Keypads). Injection molding, recognized for its speed and efficiency, infuses molten rubber into a mold under high stress, creating high-volume get rid of consistent top quality. Each method supplies unique benefits, influencing factors such as manufacturing style, cost, and rate flexibility, inevitably impacting the efficiency and life expectancy of rubber keypads in numerous applications

Material Option Value

Material selection plays a crucial duty in the manufacturing of rubber keypads, straight affecting their performance and resilience. The selection of rubber substances, such as silicone or polyurethane, influences tactile comments, resistance to use, and environmental longevity. Top notch products assure that keypads can endure comprehensive use, keeping their performance over time. Additionally, the formulation of rubber influences its resistance to temperature level changes and direct exposure to chemicals, which are vital for devices in numerous environments. Employing sophisticated manufacturing techniques, such as compression or shot molding, more improves the architectural stability of keypads. Eventually, mindful material option and production processes contribute substantially to the overall high quality, longevity, and customer useful site complete satisfaction of rubber keypads in today's innovation landscape.

Future Fads in Rubber Keypad Innovation

As technology proceeds to evolve, the future of rubber keypad technology appears appealing, with innovations positioned to boost performance and individual experience. One noteworthy trend is the integration of touch-sensitive technology, enabling capacitive responses that mimics the feel of typical buttons while offering boosted responsiveness. Furthermore, the advancement of antimicrobial materials is most likely to acquire traction, resolving hygiene concerns in public and shared gadgets.

Personalization options are expected to expand, permitting customers to personalize essential designs and responsive responses, consequently catering to diverse requirements. The consolidation of clever innovation, such as connection functions, may also emerge, permitting rubber keypads to interact with other devices perfectly. As suppliers focus on sustainability, eco-friendly products are expected to become much more widespread, straightening with international ecological objectives. In general, these trends assure to change rubber keypads, making them more functional, easy to use, and eco conscious in the technology landscape.

Often Asked Concerns

How Do Rubber Keypads Contrast in Expense to Other Keypad Kinds?

Rubber keypads usually use an affordable service compared to various other keypad types, such as membrane layer or mechanical choices. Their reduced production costs and longevity make them an eye-catching choice for numerous applications in innovation.

What Are the Ecological Effects of Rubber Keypad Production?

The environmental impacts of rubber keypad manufacturing include source exhaustion, power consumption, and contamination from producing procedures. Additionally, incorrect disposal can cause plastic waste, contributing to environmental deterioration and hurting communities if not managed responsibly.

Can Rubber Keypads Be Used Outdoors?

Rubber keypads can be made use of outdoors as a result of their resilience and resistance to weather aspects. Their longevity may depend on the high quality of materials made use of and the certain environmental problems they are revealed to.

What Upkeep Is Required for Rubber Keypads?

Rubber keypads call for normal cleaning to remove dust and debris, regular examination for deterioration, and defense from extreme temperature levels. Ensuring correct storage problems can expand their lifespan and maintain functionality over time.

Exactly How Do Rubber Keypads Perform in Extreme Temperatures?

Rubber keypads generally preserve functionality in extreme temperatures, exhibiting resilience to both cold and heat. Long term direct exposure may trigger material destruction, influencing their responsive reaction and general performance in harsh atmospheres.

Rubber keypads serve as a basic component in different electronic devices, supplying a responsive user interface for customer interaction. While many digital gadgets depend on touchscreens for individual interaction, rubber keypads proceed to play an important function in customer electronics. Furthermore, the soft touch of rubber gives convenience during prolonged use, making these keypads a preferred option for devices calling for extensive communication. Regardless of the expanding range of keypad materials readily available, rubber keypads offer distinctive advantages that make them a preferred selection in several applications. Rubber keypads typically supply a cost-effective service compared to other keypad kinds, such as membrane or mechanical alternatives.